Digital Twins in Manufacturing: Hype or Opportunity for South African Businesses?

Digital Twins in Manufacturing: Hype or Opportunity for South African Businesses?

The global manufacturing landscape is undergoing a profound transformation, driven by the convergence of physical and digital technologies. As the Fourth Industrial Revolution gains momentum, one technology stands out for its game-changing potential: Digital Twins. These virtual mirrors of physical systems promise to unlock new efficiencies, provide predictive insights, and secure competitive advantages. But are they feasible in the unique context of South Africa’s manufacturing sector, or just another overhyped concept in a resource-strapped economy?

This article explores whether digital twins are a genuine opportunity for South Africa’s manufacturing sector—or simply an expensive distraction. We will demystify the technology, analyze its specific benefits for local businesses, and weigh the very real challenges of implementation against the long-term rewards. The goal is to provide a strategic roadmap for business leaders and professionals seeking to understand how to leverage this powerful technology for growth and resilience.

What is a Digital Twin? Understanding the Core Concept

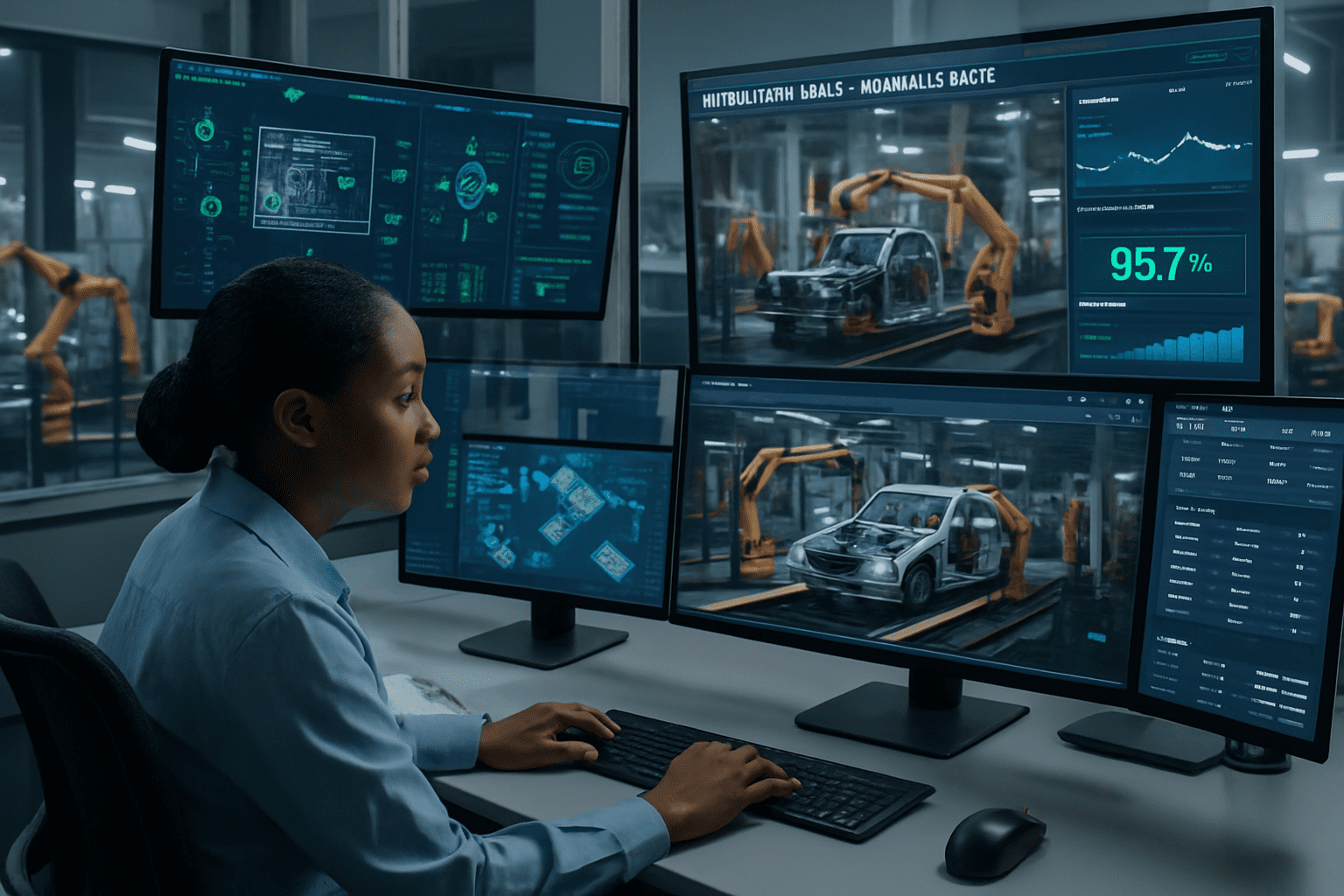

To fully appreciate the value of a digital twin, it is essential to understand what it is and what makes it different from a simple simulation. A digital twin is a real-time, digital replica of a physical asset, system, or process. It’s a dynamic, living model that is constantly updated with data from sensors, IoT devices, and other real-world data streams. This continuous data connection allows the virtual twin to accurately reflect the current state of its physical counterpart.

This constant feedback loop is its key differentiator. While a simulation can model a scenario, a digital twin can react to and adapt with a physical system in real-time. This provides unprecedented visibility and control.

Core Components of a Digital Twin:

- Physical Object: The real-world item, whether it’s a single machine, an entire production line, or a whole factory.

- Digital Model: A virtual representation, often a 3D CAD model, that captures the physical object’s geometry and functionality.

- Data Connection: The crucial link between the two, typically powered by the Industrial Internet of Things (IIoT) to provide real-time feedback.

- Analytics Engine: The “brain” of the digital twin, using machine learning and AI to analyze data, simulate outcomes, and generate predictive insights.

Think of a digital twin as a living model of your factory floor—capable of reacting and adapting in real time. For the SA manufacturing sector, which often lags behind its global competitors, this ability to react and adapt can be a game-changer. While Africa as a continent faces significant technological gaps, the potential for growth and rapid adoption is immense.

Why South African Businesses Should Care: A Path to Resilience and Competitiveness

South Africa’s manufacturing sector contributes approximately 13% of the nation’s GDP and employs over 1.7 million people. However, the sector is under enormous and unique pressure, from erratic power supply to intense global competition and rising operational costs.

Digital twin technology offers a clear pathway to navigate these challenges and build a more resilient, competitive sector. The technology provides the insights needed to solve some of the most persistent operational problems:

- Load Shedding Mitigation: By using a digital twin, manufacturers can model the impact of power outages on production schedules and reroute operations to minimize losses. This allows for proactive planning instead of reactive damage control.

- Reduced Unplanned Downtime: A digital twin can predict when a machine component is likely to fail by analyzing real-time data on temperature, vibration, and other metrics. This allows for predictive maintenance, shifting from costly, reactive repairs to efficient, planned interventions.

- Process Optimization: By running “what-if” scenarios in the virtual environment, manufacturers can identify and eliminate bottlenecks, optimize resource allocation, and improve production line efficiency without disrupting physical operations.

- Increased Production Flexibility: Digital twins enable companies to simulate and test new products or process changes in a virtual environment, dramatically reducing the time and cost associated with physical prototyping and testing.

These applications offer a clear path to improving key ROI areas for South African businesses, including predictive maintenance, process optimization, and real-time decision-making.

South African Success Stories: Proof of Concept in a Local Context

While global examples are numerous, some pioneering South African businesses are already demonstrating the tangible benefits of digital twins. These local case studies provide a compelling proof of concept for the wider industry.

1. Mercedes-Benz South Africa (MBSA) – East London MBSA is a prime example of an automotive giant leveraging technology to its advantage.

- Use Case: The company implemented Siemens’ Digital Industries Software to create a digital twin of its final assembly line at its East London plant. This virtual model allowed engineers to simulate and optimize workflows before making a single physical change to the production floor.

- Results: The impact was significant. Unscheduled downtime was reduced from 12.4% to a remarkable 5.7%, while the assembly defect rate fell from 4.9% to 2.1%. Crucially, line simulation time, which previously took days, was reduced to a matter of minutes. As one MBSA engineer noted, “It allowed us to visualize and optimize workflows before making physical changes.”

2. Autocast South Africa – Port Elizabeth This case study highlights that a full-scale, expensive implementation is not always necessary.

- Use Case: A more focused, agile approach was taken, with Autocast developing a basic digital twin of its sand-moulding machinery using open-source tools. This allowed the team to monitor performance and gain insights without a massive capital outlay.

- Impact: The results were immediate and measurable. The company saw a 16% improvement in tooling precision, and engineers were able to detect operational inefficiencies without shutting down the entire line. The return on investment for this targeted project was achieved within just nine months.

These examples show that whether you are a large multinational or a local SME, digital twin adoption is a viable and valuable strategy.

Navigating the Local Hurdles: Challenges to Adoption in SA

Despite the clear opportunities, the widespread adoption of digital twin technology in South Africa faces significant and unique challenges that cannot be ignored.

1. High Initial Investment: The capital expenditure required for a full-scale digital twin solution can be a major barrier. This includes the cost of:

- High-quality sensors and IIoT devices.

- Cloud platforms (like Microsoft Azure or Amazon Web Services) to store and process vast amounts of data.

- Specialized software and a skilled analytics team to manage the digital twin.

2. The Skills Gap: South Africa faces a digital talent drought. A survey by Accenture in 2024 revealed that 52% of respondents cited the availability of skills as a key barrier to adoption. Local universities are only now beginning to introduce IoT, machine learning, and simulation modules into engineering programs, leaving a significant gap between the technology’s potential and the human capital required to leverage it.

3. Legacy Infrastructure: Many small and medium-sized manufacturers still operate with outdated, paper-based tracking systems and machinery. Integrating a modern, data-intensive technology like a digital twin into these environments is complex, time-consuming, and often requires a complete overhaul of existing infrastructure, making it a difficult sell for management.

4. Unreliable Energy Supply: As a core component of Industry 4.0, a digital twin relies on a constant flow of real-time data. Load shedding and power supply issues disrupt this data flow, compromising the accuracy and effectiveness of the digital twin. This instability undermines the very foundation of the technology, making its implementation a riskier proposition than in more stable economies.

A 2024 survey by Accenture South Africa highlighted these challenges, with 67% of respondents citing the cost of implementation as the primary barrier, followed by skills availability (52%), system compatibility (44%), and power supply issues (38%).

Global Lessons for Local Implementation: A Strategic Roadmap

South African manufacturers can learn from the successes and failures of global pioneers to implement a digital twin strategy effectively.

- Start with Simulations: Instead of a full, capital-intensive implementation, begin with digital simulations (CAD models + physics-based modeling) to identify immediate benefits and build internal expertise. This reduces risk and provides a clear ROI case for further investment.

- Train and Upskill Existing Employees: Partner with universities and training institutions to upskill your current workforce in data analytics, IoT, and machine learning. This is often more cost-effective than trying to hire new talent in a competitive market.

- Utilize Cloud-Based “Digital Twin-as-a-Service” (DTaaS) Models: These subscription-based services lower the barrier to entry by reducing the need for massive upfront capital expenditure on hardware and software. They allow businesses to start small and scale up as their needs and capabilities grow.

How Digital Twins Support ESG and Sustainability in SA

In addition to operational benefits, digital twins can be a powerful tool for meeting critical ESG (Environmental, Social, and Governance) targets. South African manufacturers are under increasing pressure to comply with carbon tax regulations, meet ESG reporting standards, and improve resource efficiency.

- Reducing Emissions: A digital twin can be used to model and optimize a factory’s energy consumption, identify areas of waste, and simulate cleaner, more efficient production layouts.

- Water Management: In a water-scarce country, a digital twin can forecast water usage and identify opportunities for conservation and recycling, a critical benefit for a resource-intensive sector.

Case Study: Sasol, a key player in South Africa’s energy and chemical industries, is piloting a digital twin of its emissions stack. This model allows the company to predict and model NOx and SOx outputs, enabling it to take proactive measures to reduce emissions before they occur, demonstrating a clear commitment to environmental stewardship.

Hype or Opportunity? The Final Verdict

So, are digital twins just hype, or a genuine opportunity for South Africa? The answer is nuanced. They are not hype, but they are also not a simple, plug-and-play solution. In South Africa’s challenging manufacturing environment, they present a massive opportunity if implemented strategically and with a clear focus on a rapid return on investment.

Digital twins are tools—not a magic solution to all problems. To succeed, South African industries need more than just the technology; they need a commitment to:

- Skilled People: Investing in education and training to create a workforce capable of managing and leveraging these technologies.

- Supportive Policies: Government incentives and a predictable regulatory environment that encourages innovation and investment.

- Real Commitment to Digital Transformation: A willingness from business leaders to embrace change, start small, and build a culture that values data-driven decision-making.

By tackling these challenges head-on, digital twins can help South Africa’s manufacturers become more globally competitive, energy-efficient, and operationally resilient. While the upfront costs and complexity are real, the longer-term rewards—cost savings, ESG compliance, and export readiness—make the investment a strategic imperative for a sector that is vital to the nation’s economic future..